The gas transport business changes more rapidly than many other competitive markets. The pressure to change arises from both regulatory requirements and the behavior of market participants. As a result, the German natural gas market is organized in one market area, in which hundreds of network operators operate as if they were one entity. The coordination effort this requires is hard to imagine for an outsider.

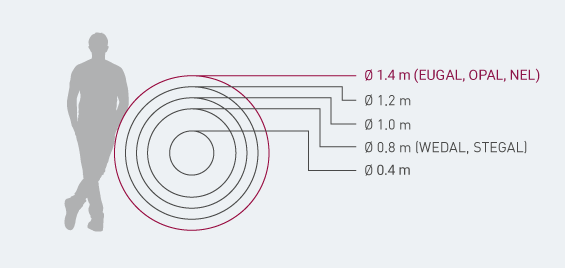

Gas pipelines require technical expertise as well as in-depth dialog with the public, politicians, authorities and land owners. In addition, we are developing our network in the middle of Europe, in compliance with European and national regulation, and in partnership with neighboring network operators. For example, the most recent GASCADE pipeline: EUGAL is 480 kilometers long and has been strengthening the gas transport network in the heart of Europe since January 2020.

The operation and dispatching of a pipeline system is a business that requires attention around the clock and is impacted by many factors: Compressors generate the necessary pressure, while instruments and valves control the gas flows and route the gas efficiently and remotely.

A host of complex operations are controlled and carried out here day and night by the dispatching center, all to ensure that gas supply runs smoothly.

We build pipelines. For tomorrow's Gas market.

Whether it’s hydrogen, climate-neutral gases or declining natural gas production within Europe, the gas market is changing. Transport routes also change accordingly. In this context, GASCADE's pipeline network ssumes a critical role in taking the natural gas and climate-neutral gases to where they are needed both now and in the future, thus guaranteeing supply security for many decades to come.

Gas transport through pipelines is equipped with a host of safety precautions. Construction supervision also ensures safety – equipped with state-of-the-art technology, it is responsible for making sure that the construction of pipelines runs smoothly. In all our projects, health, safety and environmental protection take top priority.

This is why our Health, Safety & Environment (HSE) program is an integral part of our philosophy. All processes are certified in accordance with DIN ISO 9001 and thus quality-assured.

The following objectives are of special significance to us:

- Zero accident strategy for people and the environment

- Comprehensive protective measures to ensure a safe, healthy working environment

- Timely information and involvement of the people on the ground