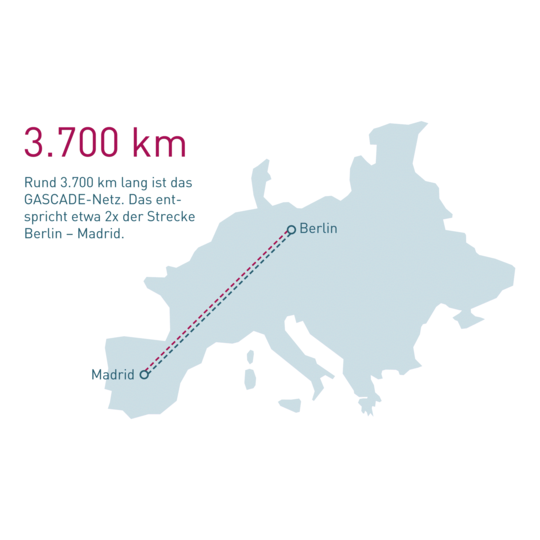

Our network

For Germany and Europe

GASCADE currently transports natural gas and soon also hydrogen – safely, reliably and efficiently. Set in the heart of Europe, our 3,700-kilometre-long pipeline network connects different sources with the major consumption centres in Germany and Europe. We transport energy over long distances to exactly where it is needed. We are constantly developing the pipeline system to also guarantee high supply security in the era of energy transition.

The 480-km-long European Gas Pipeline (EUGAL) runs in two strings from the Baltic through Mecklenburg-Western Pomerania and as far as Brandenburg. Through Saxony and over the border to the Czech Republic, it runs in just one string. EUGAL's full transport capacity has been available for marketing since April 2021.

Measuring 679 kilometres in length on the north-south axis, the Central Germany gas link MIDAL is the central element of our pipeline system. Since the end of 1993, it has connected landing points for gas from sources in Northwestern Europe with the German consumption centres. The MIDAL runs from Bunde to Rehden and then on to Reckrod and Ludwigshafen. Our STEGAL, WEDAL and RHG pipelines branch off from the MIDAL.

The North-West pipeline link (NOWAL) was commissioned in 2017. It is 26 kilometres long and connects the GASCADE pipeline system near Rehden with the OGE network in Westphalia, That increases the transport capacity between the entry points in North and Eastern Germany and the consumption centres in Western and Southern Germany.

The Ostsee Anbindungsleitung (OAL) connects the liquefied natural gas (LNG) terminal in the port of Mukran with the German pipeline system in Lubmin. GASCADE completed construction of the approximately 50-kilometre-long offshore pipeline in January 2024. Substantial transport capacities can be provided in Lubmin with the EUGAL and OPAL gas pipelines to transport the gas from the coast in the north-east to the main centres of consumption in Germany as well as in Central and South-Eastern Europe.

The Baltic Sea Pipeline Link (OPAL) was completed in 2009. The 473-km-long OPAL, which can transport up to 36 billion cubic meters of natural gas per year, runs from Greifswald on the Baltic coast through the German states of Mecklenburg Western Pomerania, Brandenburg, and Saxony to the Czech Republic.

One of the branch sections of the MIDAL is the Rehden-Hamburg gas pipeline (RHG). The joint project by GASCADE and E.ON Hanse, measuring 132 kilometres in length, has enabled natural gas to be transported to Greater Hamburg since June 1994.

The 314-kilometre-long Saxony-Thuringia natural gas pipeline (STEGAL) was commissioned in 1992. It connects the Czech and Slovakian pipeline systems with the German network and flows into the MIDAL. Over a length of 97 kilometres, two strings of the STEGAL run parallel. The STEGAL is part of the hydrogen project Flow – making hydrogen happen and is to be retrofitted in the first phase of the project to transport hydrogen by 2025.

Since 1997, the Western German gas link WEDAL has connected the German and Belgian pipeline systems over a distance of 321 kilometres. Gas volumes can be transported on the WEDAL both from east to west and west to east. Gas volumes currently flow primarily from (North)western European sources and regasified LNG into the German pipeline system.

EUGAL documentary: The film about the project

Planning and building EUGAL were a challenge for everyone involved. Key planning and construction steps were filmed for the EUGAL documentary film. The story is told by those actively involved in the project. Impressive scenes were produced with strong images and personal impressions. Enjoy watching it!

Our stations

put pressure back into the gas.

On its route from the source to consumers, natural gas travels many thousands of kilometres in large pipelines, during which it loses pressure as the molecules in the flow of gas rub against each other and the inside of the pipe. This loss has to be compensated for. That is done by GASCADE's eleven nationwide compressor stations, which are spaced at around 250 kilometres apart in the pipeline network.

Up to 5,700 revolutions a minute

Natural gas compressors are the heart of those stations. Several impellers arranged behind each other on a shaft in a steel casing rotate at a speed of up to 5,700 revolutions a minute, spinning the molecules of the inflowing gas outwards and so compressing them more densely together. Gas turbines like those used in aircraft – and the steam turbine drive the compressors. For the purpose of noise control, the gas turbines are located in sound enclosures, which are in turn located in compressor houses.

The gas volume is reduced when it is compressed. That means more energy can be transported through the pipeline. The pipeline's capacity increases – and so does supply security for customers.

The Mallnow compressor station can receive natural gas from the JAMAL and transport is via the JAGAL towards Western Germany.

Located in the heart of the Central Ore Mountains, the Olbernhau compressor station ensures the necessary pressure on the STEGAL. Olbernhau was GASCADE's first compressor station and was commissioned in the fall of 1992.

Radeland compressor station

The Radeland compressor station was built in Baruth/Mark for transporting large quantities on the OPAL gas pipeline – half way between the Baltic coast and the connection to the Czech transport infrastructure. The compressor station has three gas turbines with a total capacity of almost 100 megawatts.

Radeland 2 compressor station

South of Berlin in Baruth/Mark, Brandenburg, GASCADE has built one of the most modern compressor stations in Western Europe, Radeland 2. The station has been part of the infrastructure for EUGAL since 2021. On the site, covering an area of more than ten hectares, three compressors raise the pressure of the gas, which can be routed both to the west and the south.

The Reckrod compressor station is located in the centre of Germany. The MIDAL and STEGAL gas pipelines come together at this station at Eiterfeld. From here, the gas can be transported in all directions.

The station is currently being expanded to increase the transport capacity towards Southern Germany: Reckrod 2 will be built to the south of the existing compressor station and be connected to the existing gas pipelines MIDAL Central, MIDAL South, MIDAL South Loop (MIDAL: Central German Pipeline Link) and STEGAL (Saxony-Thuringia Gas Pipeline).

A compressor station is located south of Bremen in the Lower Saxony town of Rehden in the largest GASCADE pipeline node: This is where the gas pipelines NEL, MIDAL, RHG and NOWAL converge. The Rehden storage facility, owned by SEFE, is also accessible via this node. Thanks to modern technology, the gas can be transported flexibly in all directions. The facility is to be expanded by 2026 in order to increase capacity eastwards.

In Western Germany, between Cologne and Aachen, the Weisweiler compressor station ensures the necessary pressure in the WEDAL gas pipeline and allows gas to be exchanged with Western Europe.

If you are planning construction projects in the vicinity of our pipelines, we check them with a view to the safety of our facilities. Before starting any construction work, it is essential to obtain comprehensive pipeline information in order to avoid damage to underground supply lines.

Do you want to make a construction and planning enquiry? GASCADE uses the German Nationwide Information System for Pipeline Research (BIL) to answer your enquiry. The portal offers a complete digital workflow for pipeline information – and the best way for you to formulate your enquiry quickly, free of charge and in a legally secure manner.

Please submit your third-party planning inquiries via the portal of the German national information system for pipeline inquiries BIL.

The easy-to-follow menu navigation guides you safely through the process. All the necessary information is requested in a structured way.

Thanks to official map backgrounds and aerial photographs, the construction project can be precisely localised. This guarantees you high-quality and complete line information from all affected operators that can be reached via BIL. In addition, you have the option of importing your planning data directly into the system as a KML file.

You submit your enquiry to BIL centrally and just once. BIL checks which utility operators are responsible and forwards the enquiry to them. The utility operator checks the enquiry and also replies via BIL. This means that all the information is bundled for you and you receive a quick response.

The BIL enquiry and documentation system ensures automatic archiving and history recording. This provides you with legally secure proof that you have duly obtained the information you require about the pipeline.

Any questions?

Dimitrius Bach

Third-party planning inquiries

Rights of way & pipeline network documentation

Telephone: +49 561 934-1372

Consequential damage

Following completion of the construction of our pipeline, consequential damage to agricultural crops may occur. This damage will be examined, assessed and compensated for by our company or by agricultural experts acting on our behalf. The prerequisite for compensating for consequential damage is that we receive notification of the damage claim in good time, at least four weeks before the damaged agricultural crops are harvested.

To simplify matters, we reserve the right to settle minor damage in a simplified procedure. This requires that the damage claim contains an estimated, but as accurate as possible, initial assessment of the damage.

For this purpose, please use only the form available on this page, and send the completed damage claim to us by e-mail, post or fax. We will then get in touch with you.

Any questions?

Holger Hübert

Consequential damage

Rights of way & pipeline network documentation

Telephone: +49 561 934-1936

Christian Peine

Consequential damage

Rights of way & pipeline network documentation

Telephone: +49 561 934-2528